-

1 Warping

General term for processes after winding concerned in preparing weaver's and knitter's warps. Methods of warping vary according to (1) the yarns employed (2) whether they are sized or not, and (3) at what state sizing takes place. There are at least seven methods of warp preparation, e.g., beam warping, direct warping, mill warping on vertical mills, section warping on horizontal mills and in cheeses on section blocks, Scotch dresser sizing, Scotch warp dressing, and Yorkshire warp dressing. Beam Warping is the system in general use for making grey cotton goods. The beam warper comprises a creel for the supply ends, which may be on double-flanged bobbins, cones or cheeses, and a beaming head which comprises mechanism for mounting and rotating a warper's beam and means for winding the yarn from the creel supply on to the beam under suitable tension. The number of ends and length of warp on a back or warper's beam is related to what is required in the weaver's beam. Assuming the weaver's beams were required to have 2928 ends, 24's warp, and 8 cuts of 96 yards each, the back beams for a set might have 2928: 6 = 488 ends, and 2 X 6 X 8 X 96 = 9216 yards. On the slasher sizing machine six back beams would be run together, thereby producing 12 weaver's beams each containing 2928 ends 768 yards long. Warp Beaming Speeds - With the old type of warp beaming machine taking supply from unrolling double-flanged bobbins, the warping speed would be about 70 yards per minute. In modern beam warpers taking supply overend from cones, the warping speed is up to 250 yards per minute. With beam barrels of 41/2-in. dia., and up to 500 yards per minute with barrels of 10-in. dia. Warp and Weft Knitted Fabrics - Warp knitted fabrics in which extra yarn is introduced in the form of weft threads which are laid in between the warp threads and their needles for the purpose of adding extra weight and for patterning purposes. Warp Loom Tapes - Narrow knitted fabrics usually less than one inch wide used for trimming garments. They are knitted on circular latch needle machines, but the tapes are flat. Direct Warping - A method used in making warps for towels, fustians, and other fabrics in which the total number of ends can be accommodated in one creel, say not more than 1,000 ends. The threads are run from the creel direct to the weaver's beam on a machine similar to that used in section beam warping. Mill Warping - There are two distinctly different methods of mill warping. On the vertical mill, which may be anything up to 20 yards in circumference, the number of ends in the complete warp is obtained by repeating the runs the required number of times, e.g., with 200 bobbins in the creel, 4 runs would give a warp of 800 ends. The length of the warp is determined by the number of revolutions made by the mill for each run. The horizontal mill is much used in Yorkshire for making woollen and worsted warps It is used to a small extent for cotton warps and is largely used for making silk and rayon warps. The mill or swift is usually about 5 yards in circumference. Its distinctive feature is the making of warps in sections which are wound on the mill in overlapping manner. The creel capacity varies from 250 to 600 ends, and with 500 ends in the creel a warp of 5,000 ends would require ten sections. Section Warping for Coloured Goods - This is a system of making coloured striped warps from hank-dyed and bleached yarns. The bobbins are creeled to pattern, one or more complete patterns to each section. Each section is the full length of the warp and is run on a small section block keywayed to fit a key on the shaft of the subsequent beaming machine where the sections are placed side by side and run on the weaver's beam. Scotch Dresser Sizing - There are two systems of warp preparation known as Scotch dressing. 1. Dresser sizing used for sizing warps for linen damasks, etc. Back beams are first made and placed in two beam creels, one on each side of the headstock. The threads from several back beams are collected in one sheet of yarn, sized by passage through a size-box, brushed by a revolving brush, dried by hot air, and passed vertically upwards where both sheets of warp threads are united and pass on to the weaver's beam in a single sheet. Scotch Warp Dressing - The other method of Scotch dressing is used in the preparation of coloured striped warps, usually from warp-dyed and bleached yarn. It consists in splitting off from ball warps previously dyed or bleached and sized, the number of ends of each colour required in the finished warp. Each group is then wound on separate flanged warpers' beams. These beams are placed in a creel and the ends drawn through a reed according to pattern, and wound finally on to the weavers' beams. Yorkshire Warp Dressing - This is a system used mostly in the preparation of coloured striped warps. It is also invaluable in preparing warps dyed and sized in warp form to prevent shadiness in the cloth. Four warps with the same number of ends in each are dyed the same colour, and in sleying, one end from each warp is put in each dent of the reed. Any tendency to shadiness arising from irregularity in dyeing is thereby effectively eliminated. In striped work the required ends are split off if necessary from a larger ball warp, sleyed to pattern in the reed, and then run under controlled tension on to the weaver's beam. The dresser uses a brush as long as the width of the warp to brush out entangled places where the threads have adhered together with size. Yorkshire dressing provides perfect warps with every thread in its proper place on the weaver's beam, no crossed or missing threads, and a minimum of knots. -

2 Ball Warping

The oldest system of warping. It is used for some coloured work, and where the warps are to be shipped or sold as ball warps. A number of threads are drawn from the warper's bobbins and gathered into a form of rope of untwisted strands. This can be done direct from the bobbins on the old-fashioned warping mill, or from sections from the sectional warper. This system will be described and illustrated under " Warping." -

3 Cross Ball Warping

A form of ball warping in which the yarn forming the warp is wound on to a large tube in open spiral coils in the form of a cheese. This is done so that the yarn is in a more convenient form for bleaching or dyeing. Only about 400 ends are used in each warp (see ball warping)Dictionary of the English textile terms > Cross Ball Warping

-

4 Beam Warping

The transferring of yam from warper's bobbins on to a large flanged beam in the form of a wide sheet. Used when preparing back beams for sizing on the slasher when several beams are run together. Each beam contains up to 500, or even more, threads with a length of 15,000 yards or more. If four beams are used of 500 threads then 4 X 500 = 2,000 threads or ends on the weaver's beam. This is termed a " set." Beam warping is also used for making beams of simple stripes in coloured work. -

5 Sectional Warping

A system of warping coloured stripes from dyed yarns. The bobbins are creeled to pattern, one or more complete patterns on each section. The required number of sections to make the warp are placed side by side on a common shaft and run off simultaneously on to the weaver's beam. Grey warps for ball sizing are also made in sections. -

6 Mill Warping

This is a system of making warps on a large revolving reel of about 18 yards diameter and used when short warps of 200 yards to 600 yards only are required. After removal from the creel the warp is wound into a ball and then sized. The system is used for the coloured and fancy trade, and in the woollen industry. -

7 Ball Warps

The warps delivered by the spinner in a ball form to the warp sizer or warp dresser (see Ball Warping) -

8 Bartrees

A wood frame used in the woollen industry for hand warping. It has strong wooden pegs projecting from it to hold the warp yarn. -

9 Bobbins

These are small appliances used in the textile trades and on which yam is wound, they are known as Cops, Pirns, Spools, Tubes, Reducing, Roving and Warping Bobbins. -

10 Broich

A wool term for the spindle in warping which holds the cops of yarn. -

11 Checker (Brat Check)

A small check effect produced by warping the ends two white, two colour, and checking in the same manner.Dictionary of the English textile terms > Checker (Brat Check)

-

12 Cone

A flangeless bobbin or cardboard tube in a taper form. The yarn is unwound over the small end of the cone which is held stationary thus avoiding over running and other difficulties associated with unwinding yarn from rotating flanged bobbins. Cones are now much used as supply to warping machines and to circular knitting machines. -

13 Corselette Cloth

This is actually a brassiere cloth, but woven about 18-in. wide, with a broad selvedge as illustrated. The warping is two threads cotton and one thread rubber covered with a fine cotton thread. The take-up of the cotton ends is 100 per cent. Coarse rayon coloured weft is used, generally pink, but cream and pale blue are sometimes seen. One quality has 30 ends 2/24's cotton and 15 ends of rubber per inch, with 50 picks of 450 denier rayon. Dobby effects are used for figuring

-

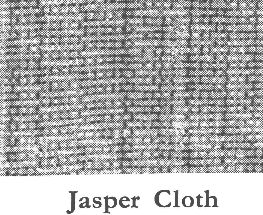

14 Jasper Cloth

A cotton jasper is produced in widths up to 92-in. made from two tones of the same colour in the warp or colour and white. The weave is plain and the general arrangement of the ends is an alternation of one white, one colour, with variations ad lib. by random insertions of two ends of either colour as indicated below: - Fawn 2-1-1-1-1-1-1-1-1-1-2-1-1-1-1-1-1-2-1-1-2-1-1 White 2-1-1-1-1-2-1-1-1-2-1-1-2-1-1-1-1-1-1-2-1-1 This only shows a part of the warping plan and the introduction of two ends of a colour can be varied infinitely at random. One make of cotton jasper has 48 ends and 30 picks per inch, 20's T., 6's W. The fabric is used for dress goods and in wide widths for quilting and curtains.

-

15 Lappers

These are loose ends of warp threads that cling to the yarn on a section when they should be taken forward on to the beam, and thus every revolution wound from the sections adds one revolution to the lapper, and if this is not cut off in reasonable time it makes an opening in the warp and consequently a soft place on the beam, or it may pick up other threads and cause serious breakages. The loose ends which cause the lappers may be threads that have run out in the warping, or broken during the beaming. -

16 Ringer

A term used in United States mills for warp ends that have snapped during the process of warping and which have stuck to the reel. -

17 Skip-Eyed Creeling

A term used in the mill to denote a method of warping very often adopted to prevent two-fold yarns from lashing together. In a creel with, say, 16 horizontal rows of bobbins creeling is started with the thread from the first bobbin in the bottom row in the first needle eye of the heck, the ninth thread goes in the second eye. Thread from bobbin No. 1 9 2 10 3 11 4 12 5 13 6 14 7 15 8 16 goes in heck eye No. 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 and in this order up every row in the creel. The threads are so separated that there is no fear of their breaking each other down.Dictionary of the English textile terms > Skip-Eyed Creeling

-

18 Sleepers

These are warp ends that are broken during the warping process and become lost. -

19 Twist Cops

Large mule cops of warp yarn which is rewound upon bobbins, cones or cheeses for the warping frame. A usual size of twist cop is 11/4-in. diameter, 71/4-in. to 8-in. long for medium and fine yarns. -

20 Wraithe

A name for the reed used in warping and beaming. It is made with stiff wires with spaces between for groups of ends according to its intended use. It is either open at the top or capable of being opened to facilitate the placing of the threads between the wires. Some wraithes are made in sections hinged together in zigzag form, which permits them to be expanded or contracted to the desired width of the warp, by turning a screw-threaded shaft.

- 1

- 2

См. также в других словарях:

Warping — Warp ing, n. 1. The act or process of one who, or that which, warps. [1913 Webster] 2. The art or occupation of preparing warp or webs for the weaver. Craig. [1913 Webster] {Warping bank}, a bank of earth raised round a field to retain water let… … The Collaborative International Dictionary of English

Warping — (von englisch warp = verformen, verzerren) von Bildern gehört in der Computergrafik zu den bildbasierten Techniken. Falls zu einem Bild die dazugehörigen Tiefenwerte existieren, ist es mittels der Warping Gleichung möglich, das Bild von einem… … Deutsch Wikipedia

Warping — Warping, eine Technik der schrittweisen Veränderung von Bildern, ähnlich dem Morphing, wobei jedoch nur mit einem Ausgangsbild, nicht aber mit einem Zielbild gearbeitet wird … Universal-Lexikon

Warping — Warp Warp (w[add]rp), v. t. [imp. & p. p. {Warped} (w[add]rpt); p. pr. & vb. n. {Warping}.] [OE. warpen; fr. Icel. varpa to throw, cast, varp a casting, fr. verpa to throw; akin to Dan. varpe to warp a ship, Sw. varpa, AS. weorpan to cast, OS.… … The Collaborative International Dictionary of English

Warping bank — Warping Warp ing, n. 1. The act or process of one who, or that which, warps. [1913 Webster] 2. The art or occupation of preparing warp or webs for the weaver. Craig. [1913 Webster] {Warping bank}, a bank of earth raised round a field to retain… … The Collaborative International Dictionary of English

Warping hook — Warping Warp ing, n. 1. The act or process of one who, or that which, warps. [1913 Webster] 2. The art or occupation of preparing warp or webs for the weaver. Craig. [1913 Webster] {Warping bank}, a bank of earth raised round a field to retain… … The Collaborative International Dictionary of English

Warping mill — Warping Warp ing, n. 1. The act or process of one who, or that which, warps. [1913 Webster] 2. The art or occupation of preparing warp or webs for the weaver. Craig. [1913 Webster] {Warping bank}, a bank of earth raised round a field to retain… … The Collaborative International Dictionary of English

Warping penny — Warping Warp ing, n. 1. The act or process of one who, or that which, warps. [1913 Webster] 2. The art or occupation of preparing warp or webs for the weaver. Craig. [1913 Webster] {Warping bank}, a bank of earth raised round a field to retain… … The Collaborative International Dictionary of English

Warping post — Warping Warp ing, n. 1. The act or process of one who, or that which, warps. [1913 Webster] 2. The art or occupation of preparing warp or webs for the weaver. Craig. [1913 Webster] {Warping bank}, a bank of earth raised round a field to retain… … The Collaborative International Dictionary of English

warping head — warping end … Dictionary of ichthyology

Warping (sailing) — In sailing, warping is a method of moving a vessel, typically against the wind, by hauling on a line attached to an anchor, a sea anchor or a fixed object, such as a bollard. In small boats, the anchor may be thrown in the intended direction of… … Wikipedia