-

1 maquiladora

f.1 maquiladora (United States).2 components factory.3 assembly plant.4 drawback industry.* * *SF Méx (Com) bonded assembly plant* * *femenino (Méx) (cross-border) assembly plant* * *femenino (Méx) (cross-border) assembly plant* * *maquila, maquiladora, cross-border plant* * *

maquiladora sustantivo femenino (Méx) (cross-border) assembly plant

* * *maquiladora nfCAm, Méx = bonded assembly plant set up by a foreign firm near the US border, US maquiladoraMAQUILADORASIn the 1980s many non-Mexican companies set up assembly plants in areas along the US-Mexican border. They were attracted by the low wages, special tax concessions and the proximity to the US market. They produce many kinds of products, but usually by assembling parts manufactured elsewhere, and by law they must re-export 80 percent of their production. Today these maquiladoras are an important source of income for Mexico and they employ more than a million Mexicans – mostly women. The managers are usually foreigners, whereas the hourly-paid workers, who have little job security and few benefits, are Mexican. -

2 элементы оборудования заводского исполнения

элементы оборудования заводского исполнения

—

[А.С.Гольдберг. Англо-русский энергетический словарь. 2006 г.]Тематики

EN

Русско-английский словарь нормативно-технической терминологии > элементы оборудования заводского исполнения

-

3 модульный центр обработки данных (ЦОД)

модульный центр обработки данных (ЦОД)

-

[Интент]Параллельные тексты EN-RU

[ http://dcnt.ru/?p=9299#more-9299]

Data Centers are a hot topic these days. No matter where you look, this once obscure aspect of infrastructure is getting a lot of attention. For years, there have been cost pressures on IT operations and this, when the need for modern capacity is greater than ever, has thrust data centers into the spotlight. Server and rack density continues to rise, placing DC professionals and businesses in tighter and tougher situations while they struggle to manage their IT environments. And now hyper-scale cloud infrastructure is taking traditional technologies to limits never explored before and focusing the imagination of the IT industry on new possibilities.

В настоящее время центры обработки данных являются широко обсуждаемой темой. Куда ни посмотришь, этот некогда малоизвестный аспект инфраструктуры привлекает все больше внимания. Годами ИТ-отделы испытывали нехватку средств и это выдвинуло ЦОДы в центр внимания, в то время, когда необходимость в современных ЦОДах стала как никогда высокой. Плотность серверов и стоек продолжают расти, все больше усложняя ситуацию для специалистов в области охлаждения и организаций в их попытках управлять своими ИТ-средами. И теперь гипермасштабируемая облачная инфраструктура подвергает традиционные технологии невиданным ранее нагрузкам, и заставляет ИТ-индустрию искать новые возможности.

At Microsoft, we have focused a lot of thought and research around how to best operate and maintain our global infrastructure and we want to share those learnings. While obviously there are some aspects that we keep to ourselves, we have shared how we operate facilities daily, our technologies and methodologies, and, most importantly, how we monitor and manage our facilities. Whether it’s speaking at industry events, inviting customers to our “Microsoft data center conferences” held in our data centers, or through other media like blogging and white papers, we believe sharing best practices is paramount and will drive the industry forward. So in that vein, we have some interesting news to share.

В компании MicroSoft уделяют большое внимание изучению наилучших методов эксплуатации и технического обслуживания своей глобальной инфраструктуры и делятся результатами своих исследований. И хотя мы, конечно, не раскрываем некоторые аспекты своих исследований, мы делимся повседневным опытом эксплуатации дата-центров, своими технологиями и методологиями и, что важнее всего, методами контроля и управления своими объектами. Будь то доклады на отраслевых событиях, приглашение клиентов на наши конференции, которые посвящены центрам обработки данных MicroSoft, и проводятся в этих самых дата-центрах, или использование других средств, например, блоги и спецификации, мы уверены, что обмен передовым опытом имеет первостепенное значение и будет продвигать отрасль вперед.

Today we are sharing our Generation 4 Modular Data Center plan. This is our vision and will be the foundation of our cloud data center infrastructure in the next five years. We believe it is one of the most revolutionary changes to happen to data centers in the last 30 years. Joining me, in writing this blog are Daniel Costello, my director of Data Center Research and Engineering and Christian Belady, principal power and cooling architect. I feel their voices will add significant value to driving understanding around the many benefits included in this new design paradigm.

Сейчас мы хотим поделиться своим планом модульного дата-центра четвертого поколения. Это наше видение и оно будет основанием для инфраструктуры наших облачных дата-центров в ближайшие пять лет. Мы считаем, что это одно из самых революционных изменений в дата-центрах за последние 30 лет. Вместе со мной в написании этого блога участвовали Дэниел Костелло, директор по исследованиям и инжинирингу дата-центров, и Кристиан Белади, главный архитектор систем энергоснабжения и охлаждения. Мне кажется, что их авторитет придаст больше веса большому количеству преимуществ, включенных в эту новую парадигму проектирования.

Our “Gen 4” modular data centers will take the flexibility of containerized servers—like those in our Chicago data center—and apply it across the entire facility. So what do we mean by modular? Think of it like “building blocks”, where the data center will be composed of modular units of prefabricated mechanical, electrical, security components, etc., in addition to containerized servers.

Was there a key driver for the Generation 4 Data Center?Наши модульные дата-центры “Gen 4” будут гибкими с контейнерами серверов – как серверы в нашем чикагском дата-центре. И гибкость будет применяться ко всему ЦОД. Итак, что мы подразумеваем под модульностью? Мы думаем о ней как о “строительных блоках”, где дата-центр будет состоять из модульных блоков изготовленных в заводских условиях электрических систем и систем охлаждения, а также систем безопасности и т.п., в дополнение к контейнеризованным серверам.

Был ли ключевой стимул для разработки дата-центра четвертого поколения?

If we were to summarize the promise of our Gen 4 design into a single sentence it would be something like this: “A highly modular, scalable, efficient, just-in-time data center capacity program that can be delivered anywhere in the world very quickly and cheaply, while allowing for continued growth as required.” Sounds too good to be true, doesn’t it? Well, keep in mind that these concepts have been in initial development and prototyping for over a year and are based on cumulative knowledge of previous facility generations and the advances we have made since we began our investments in earnest on this new design.Если бы нам нужно было обобщить достоинства нашего проекта Gen 4 в одном предложении, это выглядело бы следующим образом: “Центр обработки данных с высоким уровнем модульности, расширяемости, и энергетической эффективности, а также возможностью постоянного расширения, в случае необходимости, который можно очень быстро и дешево развертывать в любом месте мира”. Звучит слишком хорошо для того чтобы быть правдой, не так ли? Ну, не забывайте, что эти концепции находились в процессе начальной разработки и создания опытного образца в течение более одного года и основываются на опыте, накопленном в ходе развития предыдущих поколений ЦОД, а также успехах, сделанных нами со времени, когда мы начали вкладывать серьезные средства в этот новый проект.

One of the biggest challenges we’ve had at Microsoft is something Mike likes to call the ‘Goldilock’s Problem’. In a nutshell, the problem can be stated as:

The worst thing we can do in delivering facilities for the business is not have enough capacity online, thus limiting the growth of our products and services.Одну из самых больших проблем, с которыми приходилось сталкиваться Майкрософт, Майк любит называть ‘Проблемой Лютика’. Вкратце, эту проблему можно выразить следующим образом:

Самое худшее, что может быть при строительстве ЦОД для бизнеса, это не располагать достаточными производственными мощностями, и тем самым ограничивать рост наших продуктов и сервисов.The second worst thing we can do in delivering facilities for the business is to have too much capacity online.

А вторым самым худшим моментом в этой сфере может слишком большое количество производственных мощностей.

This has led to a focus on smart, intelligent growth for the business — refining our overall demand picture. It can’t be too hot. It can’t be too cold. It has to be ‘Just Right!’ The capital dollars of investment are too large to make without long term planning. As we struggled to master these interesting challenges, we had to ensure that our technological plan also included solutions for the business and operational challenges we faced as well.

So let’s take a high level look at our Generation 4 designЭто заставило нас сосредоточиваться на интеллектуальном росте для бизнеса — refining our overall demand picture. Это не должно быть слишком горячим. И это не должно быть слишком холодным. Это должно быть ‘как раз, таким как надо!’ Нельзя делать такие большие капиталовложения без долгосрочного планирования. Пока мы старались решить эти интересные проблемы, мы должны были гарантировать, что наш технологический план будет также включать решения для коммерческих и эксплуатационных проблем, с которыми нам также приходилось сталкиваться.

Давайте рассмотрим наш проект дата-центра четвертого поколенияAre you ready for some great visuals? Check out this video at Soapbox. Click here for the Microsoft 4th Gen Video.

It’s a concept video that came out of my Data Center Research and Engineering team, under Daniel Costello, that will give you a view into what we think is the future.

From a configuration, construct-ability and time to market perspective, our primary goals and objectives are to modularize the whole data center. Not just the server side (like the Chicago facility), but the mechanical and electrical space as well. This means using the same kind of parts in pre-manufactured modules, the ability to use containers, skids, or rack-based deployments and the ability to tailor the Redundancy and Reliability requirements to the application at a very specific level.

Посмотрите это видео, перейдите по ссылке для просмотра видео о Microsoft 4th Gen:

Это концептуальное видео, созданное командой отдела Data Center Research and Engineering, возглавляемого Дэниелом Костелло, которое даст вам наше представление о будущем.

С точки зрения конфигурации, строительной технологичности и времени вывода на рынок, нашими главными целями и задачами агрегатирование всего дата-центра. Не только серверную часть, как дата-центр в Чикаго, но также системы охлаждения и электрические системы. Это означает применение деталей одного типа в сборных модулях, возможность использования контейнеров, салазок, или стоечных систем, а также возможность подстраивать требования избыточности и надежности для данного приложения на очень специфичном уровне.Our goals from a cost perspective were simple in concept but tough to deliver. First and foremost, we had to reduce the capital cost per critical Mega Watt by the class of use. Some applications can run with N-level redundancy in the infrastructure, others require a little more infrastructure for support. These different classes of infrastructure requirements meant that optimizing for all cost classes was paramount. At Microsoft, we are not a one trick pony and have many Online products and services (240+) that require different levels of operational support. We understand that and ensured that we addressed it in our design which will allow us to reduce capital costs by 20%-40% or greater depending upon class.

Нашими целями в области затрат были концептуально простыми, но трудно реализуемыми. В первую очередь мы должны были снизить капитальные затраты в пересчете на один мегаватт, в зависимости от класса резервирования. Некоторые приложения могут вполне работать на базе инфраструктуры с резервированием на уровне N, то есть без резервирования, а для работы других приложений требуется больше инфраструктуры. Эти разные классы требований инфраструктуры подразумевали, что оптимизация всех классов затрат имеет преобладающее значение. В Майкрософт мы не ограничиваемся одним решением и располагаем большим количеством интерактивных продуктов и сервисов (240+), которым требуются разные уровни эксплуатационной поддержки. Мы понимаем это, и учитываем это в своем проекте, который позволит нам сокращать капитальные затраты на 20%-40% или более в зависимости от класса.For example, non-critical or geo redundant applications have low hardware reliability requirements on a location basis. As a result, Gen 4 can be configured to provide stripped down, low-cost infrastructure with little or no redundancy and/or temperature control. Let’s say an Online service team decides that due to the dramatically lower cost, they will simply use uncontrolled outside air with temperatures ranging 10-35 C and 20-80% RH. The reality is we are already spec-ing this for all of our servers today and working with server vendors to broaden that range even further as Gen 4 becomes a reality. For this class of infrastructure, we eliminate generators, chillers, UPSs, and possibly lower costs relative to traditional infrastructure.

Например, некритичные или гео-избыточные системы имеют низкие требования к аппаратной надежности на основе местоположения. В результате этого, Gen 4 можно конфигурировать для упрощенной, недорогой инфраструктуры с низким уровнем (или вообще без резервирования) резервирования и / или температурного контроля. Скажем, команда интерактивного сервиса решает, что, в связи с намного меньшими затратами, они будут просто использовать некондиционированный наружный воздух с температурой 10-35°C и влажностью 20-80% RH. В реальности мы уже сегодня предъявляем эти требования к своим серверам и работаем с поставщиками серверов над еще большим расширением диапазона температур, так как наш модуль и подход Gen 4 становится реальностью. Для подобного класса инфраструктуры мы удаляем генераторы, чиллеры, ИБП, и, возможно, будем предлагать более низкие затраты, по сравнению с традиционной инфраструктурой.

Applications that demand higher level of redundancy or temperature control will use configurations of Gen 4 to meet those needs, however, they will also cost more (but still less than traditional data centers). We see this cost difference driving engineering behavioral change in that we predict more applications will drive towards Geo redundancy to lower costs.

Системы, которым требуется более высокий уровень резервирования или температурного контроля, будут использовать конфигурации Gen 4, отвечающие этим требованиям, однако, они будут также стоить больше. Но все равно они будут стоить меньше, чем традиционные дата-центры. Мы предвидим, что эти различия в затратах будут вызывать изменения в методах инжиниринга, и по нашим прогнозам, это будет выражаться в переходе все большего числа систем на гео-избыточность и меньшие затраты.

Another cool thing about Gen 4 is that it allows us to deploy capacity when our demand dictates it. Once finalized, we will no longer need to make large upfront investments. Imagine driving capital costs more closely in-line with actual demand, thus greatly reducing time-to-market and adding the capacity Online inherent in the design. Also reduced is the amount of construction labor required to put these “building blocks” together. Since the entire platform requires pre-manufacture of its core components, on-site construction costs are lowered. This allows us to maximize our return on invested capital.

Еще одно достоинство Gen 4 состоит в том, что он позволяет нам разворачивать дополнительные мощности, когда нам это необходимо. Как только мы закончим проект, нам больше не нужно будет делать большие начальные капиталовложения. Представьте себе возможность более точного согласования капитальных затрат с реальными требованиями, и тем самым значительного снижения времени вывода на рынок и интерактивного добавления мощностей, предусматриваемого проектом. Также снижен объем строительных работ, требуемых для сборки этих “строительных блоков”. Поскольку вся платформа требует предварительного изготовления ее базовых компонентов, затраты на сборку также снижены. Это позволит нам увеличить до максимума окупаемость своих капиталовложений.

Мы все подвергаем сомнениюIn our design process, we questioned everything. You may notice there is no roof and some might be uncomfortable with this. We explored the need of one and throughout our research we got some surprising (positive) results that showed one wasn’t needed.

В своем процессе проектирования мы все подвергаем сомнению. Вы, наверное, обратили внимание на отсутствие крыши, и некоторым специалистам это могло не понравиться. Мы изучили необходимость в крыше и в ходе своих исследований получили удивительные результаты, которые показали, что крыша не нужна.

Серийное производство дата центров

In short, we are striving to bring Henry Ford’s Model T factory to the data center. http://en.wikipedia.org/wiki/Henry_Ford#Model_T. Gen 4 will move data centers from a custom design and build model to a commoditized manufacturing approach. We intend to have our components built in factories and then assemble them in one location (the data center site) very quickly. Think about how a computer, car or plane is built today. Components are manufactured by different companies all over the world to a predefined spec and then integrated in one location based on demands and feature requirements. And just like Henry Ford’s assembly line drove the cost of building and the time-to-market down dramatically for the automobile industry, we expect Gen 4 to do the same for data centers. Everything will be pre-manufactured and assembled on the pad.Мы хотим применить модель автомобильной фабрики Генри Форда к дата-центру. Проект Gen 4 будет способствовать переходу от модели специализированного проектирования и строительства к товарно-производственному, серийному подходу. Мы намерены изготавливать свои компоненты на заводах, а затем очень быстро собирать их в одном месте, в месте строительства дата-центра. Подумайте о том, как сегодня изготавливается компьютер, автомобиль или самолет. Компоненты изготавливаются по заранее определенным спецификациям разными компаниями во всем мире, затем собираются в одном месте на основе спроса и требуемых характеристик. И точно так же как сборочный конвейер Генри Форда привел к значительному уменьшению затрат на производство и времени вывода на рынок в автомобильной промышленности, мы надеемся, что Gen 4 сделает то же самое для дата-центров. Все будет предварительно изготавливаться и собираться на месте.

Невероятно энергоэффективный ЦОД

And did we mention that this platform will be, overall, incredibly energy efficient? From a total energy perspective not only will we have remarkable PUE values, but the total cost of energy going into the facility will be greatly reduced as well. How much energy goes into making concrete? Will we need as much of it? How much energy goes into the fuel of the construction vehicles? This will also be greatly reduced! A key driver is our goal to achieve an average PUE at or below 1.125 by 2012 across our data centers. More than that, we are on a mission to reduce the overall amount of copper and water used in these facilities. We believe these will be the next areas of industry attention when and if the energy problem is solved. So we are asking today…“how can we build a data center with less building”?А мы упоминали, что эта платформа будет, в общем, невероятно энергоэффективной? С точки зрения общей энергии, мы получим не только поразительные значения PUE, но общая стоимость энергии, затраченной на объект будет также значительно снижена. Сколько энергии идет на производство бетона? Нам нужно будет столько энергии? Сколько энергии идет на питание инженерных строительных машин? Это тоже будет значительно снижено! Главным стимулом является достижение среднего PUE не больше 1.125 для всех наших дата-центров к 2012 году. Более того, у нас есть задача сокращения общего количества меди и воды в дата-центрах. Мы думаем, что эти задачи станут следующей заботой отрасли после того как будет решена энергетическая проблема. Итак, сегодня мы спрашиваем себя…“как можно построить дата-центр с меньшим объемом строительных работ”?

Строительство дата центров без чиллеровWe have talked openly and publicly about building chiller-less data centers and running our facilities using aggressive outside economization. Our sincerest hope is that Gen 4 will completely eliminate the use of water. Today’s data centers use massive amounts of water and we see water as the next scarce resource and have decided to take a proactive stance on making water conservation part of our plan.

Мы открыто и публично говорили о строительстве дата-центров без чиллеров и активном использовании в наших центрах обработки данных технологий свободного охлаждения или фрикулинга. Мы искренне надеемся, что Gen 4 позволит полностью отказаться от использования воды. Современные дата-центры расходуют большие объемы воды и так как мы считаем воду следующим редким ресурсом, мы решили принять упреждающие меры и включить экономию воды в свой план.

By sharing this with the industry, we believe everyone can benefit from our methodology. While this concept and approach may be intimidating (or downright frightening) to some in the industry, disclosure ultimately is better for all of us.

Делясь этим опытом с отраслью, мы считаем, что каждый сможет извлечь выгоду из нашей методологией. Хотя эта концепция и подход могут показаться пугающими (или откровенно страшными) для некоторых отраслевых специалистов, раскрывая свои планы мы, в конечном счете, делаем лучше для всех нас.

Gen 4 design (even more than just containers), could reduce the ‘religious’ debates in our industry. With the central spine infrastructure in place, containers or pre-manufactured server halls can be either AC or DC, air-side economized or water-side economized, or not economized at all (though the sanity of that might be questioned). Gen 4 will allow us to decommission, repair and upgrade quickly because everything is modular. No longer will we be governed by the initial decisions made when constructing the facility. We will have almost unlimited use and re-use of the facility and site. We will also be able to use power in an ultra-fluid fashion moving load from critical to non-critical as use and capacity requirements dictate.

Проект Gen 4 позволит уменьшить ‘религиозные’ споры в нашей отрасли. Располагая базовой инфраструктурой, контейнеры или сборные серверные могут оборудоваться системами переменного или постоянного тока, воздушными или водяными экономайзерами, или вообще не использовать экономайзеры. Хотя можно подвергать сомнению разумность такого решения. Gen 4 позволит нам быстро выполнять работы по выводу из эксплуатации, ремонту и модернизации, поскольку все будет модульным. Мы больше не будем руководствоваться начальными решениями, принятыми во время строительства дата-центра. Мы сможем использовать этот дата-центр и инфраструктуру в течение почти неограниченного периода времени. Мы также сможем применять сверхгибкие методы использования электрической энергии, переводя оборудование в режимы критической или некритической нагрузки в соответствии с требуемой мощностью.

Gen 4 – это стандартная платформаFinally, we believe this is a big game changer. Gen 4 will provide a standard platform that our industry can innovate around. For example, all modules in our Gen 4 will have common interfaces clearly defined by our specs and any vendor that meets these specifications will be able to plug into our infrastructure. Whether you are a computer vendor, UPS vendor, generator vendor, etc., you will be able to plug and play into our infrastructure. This means we can also source anyone, anywhere on the globe to minimize costs and maximize performance. We want to help motivate the industry to further innovate—with innovations from which everyone can reap the benefits.

Наконец, мы уверены, что это будет фактором, который значительно изменит ситуацию. Gen 4 будет представлять собой стандартную платформу, которую отрасль сможет обновлять. Например, все модули в нашем Gen 4 будут иметь общепринятые интерфейсы, четко определяемые нашими спецификациями, и оборудование любого поставщика, которое отвечает этим спецификациям можно будет включать в нашу инфраструктуру. Независимо от того производите вы компьютеры, ИБП, генераторы и т.п., вы сможете включать свое оборудование нашу инфраструктуру. Это означает, что мы также сможем обеспечивать всех, в любом месте земного шара, тем самым сводя до минимума затраты и максимальной увеличивая производительность. Мы хотим создать в отрасли мотивацию для дальнейших инноваций – инноваций, от которых каждый сможет получать выгоду.

Главные характеристики дата-центров четвертого поколения Gen4To summarize, the key characteristics of our Generation 4 data centers are:

Scalable

Plug-and-play spine infrastructure

Factory pre-assembled: Pre-Assembled Containers (PACs) & Pre-Manufactured Buildings (PMBs)

Rapid deployment

De-mountable

Reduce TTM

Reduced construction

Sustainable measuresНиже приведены главные характеристики дата-центров четвертого поколения Gen 4:

Расширяемость;

Готовая к использованию базовая инфраструктура;

Изготовление в заводских условиях: сборные контейнеры (PAC) и сборные здания (PMB);

Быстрота развертывания;

Возможность демонтажа;

Снижение времени вывода на рынок (TTM);

Сокращение сроков строительства;

Экологичность;Map applications to DC Class

We hope you join us on this incredible journey of change and innovation!

Long hours of research and engineering time are invested into this process. There are still some long days and nights ahead, but the vision is clear. Rest assured however, that we as refine Generation 4, the team will soon be looking to Generation 5 (even if it is a bit farther out). There is always room to get better.

Использование систем электропитания постоянного тока.

Мы надеемся, что вы присоединитесь к нам в этом невероятном путешествии по миру изменений и инноваций!

На этот проект уже потрачены долгие часы исследований и проектирования. И еще предстоит потратить много дней и ночей, но мы имеем четкое представление о конечной цели. Однако будьте уверены, что как только мы доведем до конца проект модульного дата-центра четвертого поколения, мы вскоре начнем думать о проекте дата-центра пятого поколения. Всегда есть возможность для улучшений.So if you happen to come across Goldilocks in the forest, and you are curious as to why she is smiling you will know that she feels very good about getting very close to ‘JUST RIGHT’.

Generations of Evolution – some background on our data center designsТак что, если вы встретите в лесу девочку по имени Лютик, и вам станет любопытно, почему она улыбается, вы будете знать, что она очень довольна тем, что очень близко подошла к ‘ОПИМАЛЬНОМУ РЕШЕНИЮ’.

Поколения эволюции – история развития наших дата-центровWe thought you might be interested in understanding what happened in the first three generations of our data center designs. When Ray Ozzie wrote his Software plus Services memo it posed a very interesting challenge to us. The winds of change were at ‘tornado’ proportions. That “plus Services” tag had some significant (and unstated) challenges inherent to it. The first was that Microsoft was going to evolve even further into an operations company. While we had been running large scale Internet services since 1995, this development lead us to an entirely new level. Additionally, these “services” would span across both Internet and Enterprise businesses. To those of you who have to operate “stuff”, you know that these are two very different worlds in operational models and challenges. It also meant that, to achieve the same level of reliability and performance required our infrastructure was going to have to scale globally and in a significant way.

Мы подумали, что может быть вам будет интересно узнать историю первых трех поколений наших центров обработки данных. Когда Рэй Оззи написал свою памятную записку Software plus Services, он поставил перед нами очень интересную задачу. Ветра перемен двигались с ураганной скоростью. Это окончание “plus Services” скрывало в себе какие-то значительные и неопределенные задачи. Первая заключалась в том, что Майкрософт собиралась в еще большей степени стать операционной компанией. Несмотря на то, что мы управляли большими интернет-сервисами, начиная с 1995 г., эта разработка подняла нас на абсолютно новый уровень. Кроме того, эти “сервисы” охватывали интернет-компании и корпорации. Тем, кому приходится всем этим управлять, известно, что есть два очень разных мира в области операционных моделей и задач. Это также означало, что для достижения такого же уровня надежности и производительности требовалось, чтобы наша инфраструктура располагала значительными возможностями расширения в глобальных масштабах.

It was that intense atmosphere of change that we first started re-evaluating data center technology and processes in general and our ideas began to reach farther than what was accepted by the industry at large. This was the era of Generation 1. As we look at where most of the world’s data centers are today (and where our facilities were), it represented all the known learning and design requirements that had been in place since IBM built the first purpose-built computer room. These facilities focused more around uptime, reliability and redundancy. Big infrastructure was held accountable to solve all potential environmental shortfalls. This is where the majority of infrastructure in the industry still is today.

Именно в этой атмосфере серьезных изменений мы впервые начали переоценку ЦОД-технологий и технологий вообще, и наши идеи начали выходить за пределы общепринятых в отрасли представлений. Это была эпоха ЦОД первого поколения. Когда мы узнали, где сегодня располагается большинство мировых дата-центров и где находятся наши предприятия, это представляло весь опыт и навыки проектирования, накопленные со времени, когда IBM построила первую серверную. В этих ЦОД больше внимания уделялось бесперебойной работе, надежности и резервированию. Большая инфраструктура была призвана решать все потенциальные экологические проблемы. Сегодня большая часть инфраструктуры все еще находится на этом этапе своего развития.

We soon realized that traditional data centers were quickly becoming outdated. They were not keeping up with the demands of what was happening technologically and environmentally. That’s when we kicked off our Generation 2 design. Gen 2 facilities started taking into account sustainability, energy efficiency, and really looking at the total cost of energy and operations.

Очень быстро мы поняли, что стандартные дата-центры очень быстро становятся устаревшими. Они не поспевали за темпами изменений технологических и экологических требований. Именно тогда мы стали разрабатывать ЦОД второго поколения. В этих дата-центрах Gen 2 стали принимать во внимание такие факторы как устойчивое развитие, энергетическая эффективность, а также общие энергетические и эксплуатационные.

No longer did we view data centers just for the upfront capital costs, but we took a hard look at the facility over the course of its life. Our Quincy, Washington and San Antonio, Texas facilities are examples of our Gen 2 data centers where we explored and implemented new ways to lessen the impact on the environment. These facilities are considered two leading industry examples, based on their energy efficiency and ability to run and operate at new levels of scale and performance by leveraging clean hydro power (Quincy) and recycled waste water (San Antonio) to cool the facility during peak cooling months.

Мы больше не рассматривали дата-центры только с точки зрения начальных капитальных затрат, а внимательно следили за работой ЦОД на протяжении его срока службы. Наши объекты в Куинси, Вашингтоне, и Сан-Антонио, Техас, являются образцами наших ЦОД второго поколения, в которых мы изучали и применяли на практике новые способы снижения воздействия на окружающую среду. Эти объекты считаются двумя ведущими отраслевыми примерами, исходя из их энергетической эффективности и способности работать на новых уровнях производительности, основанных на использовании чистой энергии воды (Куинси) и рециклирования отработанной воды (Сан-Антонио) для охлаждения объекта в самых жарких месяцах.

As we were delivering our Gen 2 facilities into steel and concrete, our Generation 3 facilities were rapidly driving the evolution of the program. The key concepts for our Gen 3 design are increased modularity and greater concentration around energy efficiency and scale. The Gen 3 facility will be best represented by the Chicago, Illinois facility currently under construction. This facility will seem very foreign compared to the traditional data center concepts most of the industry is comfortable with. In fact, if you ever sit around in our container hanger in Chicago it will look incredibly different from a traditional raised-floor data center. We anticipate this modularization will drive huge efficiencies in terms of cost and operations for our business. We will also introduce significant changes in the environmental systems used to run our facilities. These concepts and processes (where applicable) will help us gain even greater efficiencies in our existing footprint, allowing us to further maximize infrastructure investments.

Так как наши ЦОД второго поколения строились из стали и бетона, наши центры обработки данных третьего поколения начали их быстро вытеснять. Главными концептуальными особенностями ЦОД третьего поколения Gen 3 являются повышенная модульность и большее внимание к энергетической эффективности и масштабированию. Дата-центры третьего поколения лучше всего представлены объектом, который в настоящее время строится в Чикаго, Иллинойс. Этот ЦОД будет выглядеть очень необычно, по сравнению с общепринятыми в отрасли представлениями о дата-центре. Действительно, если вам когда-либо удастся побывать в нашем контейнерном ангаре в Чикаго, он покажется вам совершенно непохожим на обычный дата-центр с фальшполом. Мы предполагаем, что этот модульный подход будет способствовать значительному повышению эффективности нашего бизнеса в отношении затрат и операций. Мы также внесем существенные изменения в климатические системы, используемые в наших ЦОД. Эти концепции и технологии, если применимо, позволят нам добиться еще большей эффективности наших существующих дата-центров, и тем самым еще больше увеличивать капиталовложения в инфраструктуру.

This is definitely a journey, not a destination industry. In fact, our Generation 4 design has been under heavy engineering for viability and cost for over a year. While the demand of our commercial growth required us to make investments as we grew, we treated each step in the learning as a process for further innovation in data centers. The design for our future Gen 4 facilities enabled us to make visionary advances that addressed the challenges of building, running, and operating facilities all in one concerted effort.

Это определенно путешествие, а не конечный пункт назначения. На самом деле, наш проект ЦОД четвертого поколения подвергался серьезным испытаниям на жизнеспособность и затраты на протяжении целого года. Хотя необходимость в коммерческом росте требовала от нас постоянных капиталовложений, мы рассматривали каждый этап своего развития как шаг к будущим инновациям в области дата-центров. Проект наших будущих ЦОД четвертого поколения Gen 4 позволил нам делать фантастические предположения, которые касались задач строительства, управления и эксплуатации объектов как единого упорядоченного процесса.

Тематики

Синонимы

EN

Русско-английский словарь нормативно-технической терминологии > модульный центр обработки данных (ЦОД)

-

4 recolector

m.1 collector, bill collector.2 collector, recipient.* * *► nombre masculino,nombre femenino1 picker* * *recolector, -aSM / F (Agr) picker* * ** * *= gatherer, harvester, collector.Ex. This article examines the work of hunters, gatherers, farmers, factory workers, and information handlers from the Ice Age to the Information Age.Ex. The system has 3 main components: a harvester (for collecting information), a database (for making the collection searchable), and an user interface (for making the information available).Ex. Another such collector was Sir Walter Scott himself, who even as a boy had a collection of chapbooks.----* cazador-recolector = hunter-gatherer.* * ** * *= gatherer, harvester, collector.Ex: This article examines the work of hunters, gatherers, farmers, factory workers, and information handlers from the Ice Age to the Information Age.

Ex: The system has 3 main components: a harvester (for collecting information), a database (for making the collection searchable), and an user interface (for making the information available).Ex: Another such collector was Sir Walter Scott himself, who even as a boy had a collection of chapbooks.* cazador-recolector = hunter-gatherer.* * *masculine, feminine* * *recolector, -ora♦ adj1. [maquinaria, época] harvestinghombre recolector forager♦ nm,f[persona] [de cosecha] harvester; [de fruta] picker; Am [de basura] Br refuse collector, US garbage collector♦ nmAm [vehículo] [de basura] Br dustcart, rubbish truck, US garbage truck -

5 ремонт

ремонт агрегатный — unit repair, repair by replacement of unitsремонт восстановительный — complete renovation, overhaulремонт заводской — factory overhaul, works overhaulремонт капитальный — major repair, (heavy) overhaulремонт конструкций и монтажа прибора... (заголовок) — repair of components and wiring of device...▪ Selection of the proper solder is the next step required for trouble-free repair.ремонт планово-предупредительный — preventive maintenance, planned maintenanceремонт профилактический — preventive maintenance, preventive repairремонт скоростной — high-speed repair, rapid repairремонт текущий — running repair, routine repair, routine maintenanceпроизводить (выполнять) ремонт — to perform repairs, to make repairs▪ In extreme cold even shop maintenance cannot be completed with normal speed, because the equipment must be allowed to thaw out and warm up before the mechanic can make satisfactory repairsРемонт типовых деталей, соединений и сборочных единиц — Repair of Standard Parts, Connections and UnitsПоставки машин и оборудования. Русско-английский словарь > ремонт

-

6 Ford, Henry

[br]b. 30 July 1863 Dearborn, Michigan, USAd. 7 April 1947 Dearborn, Michigan, USA[br]American pioneer motor-car maker and developer of mass-production methods.[br]He was the son of an Irish immigrant farmer, William Ford, and the oldest son to survive of Mary Litogot; his mother died in 1876 with the birth of her sixth child. He went to the village school, and at the age of 16 he was apprenticed to Flower brothers' machine shop and then at the Drydock \& Engineering Works in Detroit. In 1882 he left to return to the family farm and spent some time working with a 1 1/2 hp steam engine doing odd jobs for the farming community at $3 per day. He was then employed as a demonstrator for Westinghouse steam engines. He met Clara Jane Bryant at New Year 1885 and they were married on 11 April 1888. Their only child, Edsel Bryant Ford, was born on 6 November 1893.At that time Henry worked on steam engine repairs for the Edison Illuminating Company, where he became Chief Engineer. He became one of a group working to develop a "horseless carriage" in 1896 and in June completed his first vehicle, a "quadri cycle" with a two-cylinder engine. It was built in a brick shed, which had to be partially demolished to get the carriage out.Ford became involved in motor racing, at which he was more successful than he was in starting a car-manufacturing company. Several early ventures failed, until the Ford Motor Company of 1903. By October 1908 they had started with production of the Model T. The first, of which over 15 million were built up to the end of its production in May 1927, came out with bought-out steel stampings and a planetary gearbox, and had a one-piece four-cylinder block with a bolt-on head. This was one of the most successful models built by Ford or any other motor manufacturer in the life of the motor car.Interchangeability of components was an important element in Ford's philosophy. Ford was a pioneer in the use of vanadium steel for engine components. He adopted the principles of Frederick Taylor, the pioneer of time-and-motion study, and installed the world's first moving assembly line for the production of magnetos, started in 1913. He installed blast furnaces at the factory to make his own steel, and he also promoted research and the cultivation of the soya bean, from which a plastic was derived.In October 1913 he introduced the "Five Dollar Day", almost doubling the normal rate of pay. This was a profit-sharing scheme for his employees and contained an element of a reward for good behaviour. About this time he initiated work on an agricultural tractor, the "Fordson" made by a separate company, the directors of which were Henry and his son Edsel.In 1915 he chartered the Oscar II, a "peace ship", and with fifty-five delegates sailed for Europe a week before Christmas, docking at Oslo. Their objective was to appeal to all European Heads of State to stop the war. He had hoped to persuade manufacturers to replace armaments with tractors in their production programmes. In the event, Ford took to his bed in the hotel with a chill, stayed there for five days and then sailed for New York and home. He did, however, continue to finance the peace activists who remained in Europe. Back in America, he stood for election to the US Senate but was defeated. He was probably the father of John Dahlinger, illegitimate son of Evangeline Dahlinger, a stenographer employed by the firm and on whom he lavished gifts of cars, clothes and properties. He became the owner of a weekly newspaper, the Dearborn Independent, which became the medium for the expression of many of his more unorthodox ideas. He was involved in a lawsuit with the Chicago Tribune in 1919, during which he was cross-examined on his knowledge of American history: he is reputed to have said "History is bunk". What he actually said was, "History is bunk as it is taught in schools", a very different comment. The lawyers who thus made a fool of him would have been surprised if they could have foreseen the force and energy that their actions were to release. For years Ford employed a team of specialists to scour America and Europe for furniture, artefacts and relics of all kinds, illustrating various aspects of history. Starting with the Wayside Inn from South Sudbury, Massachusetts, buildings were bought, dismantled and moved, to be reconstructed in Greenfield Village, near Dearborn. The courthouse where Abraham Lincoln had practised law and the Ohio bicycle shop where the Wright brothers built their first primitive aeroplane were added to the farmhouse where the proprietor, Henry Ford, had been born. Replicas were made of Independence Hall, Congress Hall and the old City Hall in Philadelphia, and even a reconstruction of Edison's Menlo Park laboratory was installed. The Henry Ford museum was officially opened on 21 October 1929, on the fiftieth anniversary of Edison's invention of the incandescent bulb, but it continued to be a primary preoccupation of the great American car maker until his death.Henry Ford was also responsible for a number of aeronautical developments at the Ford Airport at Dearborn. He introduced the first use of radio to guide a commercial aircraft, the first regular airmail service in the United States. He also manufactured the country's first all-metal multi-engined plane, the Ford Tri-Motor.Edsel became President of the Ford Motor Company on his father's resignation from that position on 30 December 1918. Following the end of production in May 1927 of the Model T, the replacement Model A was not in production for another six months. During this period Henry Ford, though officially retired from the presidency of the company, repeatedly interfered and countermanded the orders of his son, ostensibly the man in charge. Edsel, who died of stomach cancer at his home at Grosse Point, Detroit, on 26 May 1943, was the father of Henry Ford II. Henry Ford died at his home, "Fair Lane", four years after his son's death.[br]Bibliography1922, with S.Crowther, My Life and Work, London: Heinemann.Further ReadingR.Lacey, 1986, Ford, the Men and the Machine, London: Heinemann. W.C.Richards, 1948, The Last Billionaire, Henry Ford, New York: Charles Scribner.IMcN -

7 Hornby, Frank

SUBJECT AREA: Domestic appliances and interiors[br]b. 15 May 1863 Liverpool, Englandd. 21 September 1936 Liverpool, England[br]English toy manufacturer and inventor of Meccano kits.[br]Frank Hornby left school at the age of 16 and worked as a clerk, at first for his father, a provision merchant, and later for D.H.Elliott, an importer of meat and livestock, for whom he became Managing Clerk. As a youth he was interested in engineering and in his own small workshop he became a skilled amateur mechanic. He made toys for his children and c.1900 he devised a constructional toy kit consisting of perforated metal strips which could be connected by bolts and nuts. He filed a patent application in January 1901 and, having failed to interest established toy manufacturers, he set up a small business in partnership with his employer, D.H. Elliott, who provided financial support. The kits were sold at first under the name of Mechanics Made Easy, but by 1907 the name Meccano had been registered as a trade mark. The business expanded rapidly and in 1908 Elliott withdrew from the partnership and Hornby continued on his own account, the company being incorporated as Meccano Ltd. Although parts for Meccano were produced at first by various manufacturers, Hornby soon acquired premises to produce all the components under his own control, and between 1910 and 1913 he established his own factory on a 5-acre (2-hectare) site at Binn's Road, Liverpool. The Meccano Magazine, a monthly publication with articles of general engineering interest, developed from a newsletter giving advice on the use of Meccano, and from the first issue in 1916 until 1924 was edited by Frank Hornby. In 1920 he introduced the clockwork Hornby trains, followed by the electric version five years later. These were gauge "0" (1 1/4 in./32 mm); the smaller gauge "00", or Hornby Dublo, was a later development. Another product of Meccano Ltd was the series of model vehicles known as Dinky toys, introduced in 1934.Frank Hornby served as a Member of Parliament for the Everton Division of Liverpool from 1931 to 1935.[br]Principal Honours and DistinctionsMP, 1931–5.Further ReadingD.J.Jeremy (ed.), 1984–6, Dictionary of Business Biography, Vol. 3, London, 345–9 (a useful biography).Proceedings of the Institution of Mechanical Engineers 127(1934):140–1 (describes the Binn's Road factory).RTS -

8 сборные строительные изделия заводского изготовления

Construction: factory produced building componentsУниверсальный русско-английский словарь > сборные строительные изделия заводского изготовления

-

9 сборные строительные компоненты заводского изготовления

Construction: factory produced building componentsУниверсальный русско-английский словарь > сборные строительные компоненты заводского изготовления

-

10 сборные строительные элементы заводского изготовления

Construction: factory produced building componentsУниверсальный русско-английский словарь > сборные строительные элементы заводского изготовления

-

11 напрямую через

Напрямую через (завод)-- Obtain the price and delivery of your selected components, and place your order with X. either through your local representative or factory direct.Русско-английский научно-технический словарь переводчика > напрямую через

-

12 посылать заказ в

Посылать заказ в-- Obtain the price and delivery of your selected components, and place your order with X. either through your local representative or factory direct.Русско-английский научно-технический словарь переводчика > посылать заказ в

-

13 kanban

Opsa Japanese production management technique that uses cards attached to components to monitor and control workflow in a factory. The kanban system was first developed by the car manufacturer Toyota. -

14 Bramah, Joseph

SUBJECT AREA: Civil engineering, Domestic appliances and interiors, Land transport, Mechanical, pneumatic and hydraulic engineering, Public utilities[br]b. 2 April 1749 Stainborough, Yorkshire, Englandd. 9 December 1814 Pimlico, London, England[br]English inventor of the second patented water-closet, the beer-engine, the Bramah lock and, most important, the hydraulic press.[br]Bramah was the son of a tenant farmer and was educated at the village school before being apprenticed to a local carpenter, Thomas Allot. He walked to London c.1773 and found work with a Mr Allen that included the repair of some of the comparatively rare water-closets of the period. He invented and patented one of his own, which was followed by a water cock in 1783. His next invention, a greatly improved lock, involved the devising of a number of special machine tools, for it was one of the first devices involving interchangeable components in its manufacture. In this he had the help of Henry Maudslay, then a young and unknown engineer, who became Bramah's foreman before setting up business on his own. In 1784 he moved his premises from Denmark Street, St Giles, to 124 Piccadilly, which was later used as a showroom when he set up a factory in Pimlico. He invented an engine for putting out fires in 1785 and 1793, in effect a reciprocating rotary-vane pump. He undertook the refurbishment and modernization of Norwich waterworks c.1793, but fell out with Robert Mylne, who was acting as Consultant to the Norwich Corporation and had produced a remarkably vague specification. This was Bramah's only venture into the field of civil engineering.In 1797 he acted as an expert witness for Hornblower \& Maberley in the patent infringement case brought against them by Boulton and Watt. Having been cut short by the judge, he published his proposed evidence in "Letter to the Rt Hon. Sir James Eyre, Lord Chief Justice of the Common Pleas…etc". In 1795 he was granted his most important patent, based on Pascal's Hydrostatic Paradox, for the hydraulic press which also incorporated the concept of hydraulics for the transmission of both power and motion and was the foundation of the whole subsequent hydraulic industry. There is no truth in the oft-repeated assertion originating from Samuel Smiles's Industrial Biography (1863) that the hydraulic press could not be made to work until Henry Maudslay invented the self-sealing neck leather. Bramah used a single-acting upstroking ram, sealed only at its base with a U-leather. There was no need for a neck leather.He also used the concept of the weight-loaded, in this case as a public-house beer-engine. He devised machinery for carbonating soda water. The first banknote-numbering machine was of his design and was bought by the Bank of England. His development of a machine to cut twelve nibs from one goose quill started a patent specification which ended with the invention of the fountain pen, patented in 1809. His coach brakes were an innovation that was followed bv a form of hydropneumatic carriage suspension that was somewhat in advance of its time, as was his patent of 1812. This foresaw the introduction of hydraulic power mains in major cities and included the telescopic ram and the air-loaded accumulator.In all Joseph Bramah was granted eighteen patents. On 22 March 1813 he demonstrated a hydraulic machine for pulling up trees by the roots in Hyde Park before a large crowd headed by the Duke of York. Using the same machine in Alice Holt Forest in Hampshire to fell timber for ships for the Navy, he caught a chill and died soon after at his home in Pimlico.[br]Bibliography1778, British patent no. 1177 (water-closet). 1784, British patent no. 1430 (Bramah Lock). 1795, British patent no. 2045 (hydraulic press). 1809, British patent no. 3260 (fountain pen). 1812, British patent no. 3611.Further ReadingI.McNeil, 1968, Joseph Bramah, a Century of Invention.S.Smiles, 1863, Industrial Biography.H.W.Dickinson, 1942, "Joseph Bramah and his inventions", Transactions of the Newcomen Society 22:169–86.IMcN -

15 Edison, Thomas Alva

SUBJECT AREA: Architecture and building, Automotive engineering, Electricity, Electronics and information technology, Metallurgy, Photography, film and optics, Public utilities, Recording, Telecommunications[br]b. 11 February 1847 Milan, Ohio, USAd. 18 October 1931 Glenmont[br]American inventor and pioneer electrical developer.[br]He was the son of Samuel Edison, who was in the timber business. His schooling was delayed due to scarlet fever until 1855, when he was 8½ years old, but he was an avid reader. By the age of 14 he had a job as a newsboy on the railway from Port Huron to Detroit, a distance of sixty-three miles (101 km). He worked a fourteen-hour day with a stopover of five hours, which he spent in the Detroit Free Library. He also sold sweets on the train and, later, fruit and vegetables, and was soon making a profit of $20 a week. He then started two stores in Port Huron and used a spare freight car as a laboratory. He added a hand-printing press to produce 400 copies weekly of The Grand Trunk Herald, most of which he compiled and edited himself. He set himself to learn telegraphy from the station agent at Mount Clements, whose son he had saved from being run over by a freight car.At the age of 16 he became a telegraphist at Port Huron. In 1863 he became railway telegraphist at the busy Stratford Junction of the Grand Trunk Railroad, arranging a clock with a notched wheel to give the hourly signal which was to prove that he was awake and at his post! He left hurriedly after failing to hold a train which was nearly involved in a head-on collision. He usually worked the night shift, allowing himself time for experiments during the day. His first invention was an arrangement of two Morse registers so that a high-speed input could be decoded at a slower speed. Moving from place to place he held many positions as a telegraphist. In Boston he invented an automatic vote recorder for Congress and patented it, but the idea was rejected. This was the first of a total of 1180 patents that he was to take out during his lifetime. After six years he resigned from the Western Union Company to devote all his time to invention, his next idea being an improved ticker-tape machine for stockbrokers. He developed a duplex telegraphy system, but this was turned down by the Western Union Company. He then moved to New York.Edison found accommodation in the battery room of Law's Gold Reporting Company, sleeping in the cellar, and there his repair of a broken transmitter marked him as someone of special talents. His superior soon resigned, and he was promoted with a salary of $300 a month. Western Union paid him $40,000 for the sole rights on future improvements on the duplex telegraph, and he moved to Ward Street, Newark, New Jersey, where he employed a gathering of specialist engineers. Within a year, he married one of his employees, Mary Stilwell, when she was only 16: a daughter, Marion, was born in 1872, and two sons, Thomas and William, in 1876 and 1879, respectively.He continued to work on the automatic telegraph, a device to send out messages faster than they could be tapped out by hand: that is, over fifty words per minute or so. An earlier machine by Alexander Bain worked at up to 400 words per minute, but was not good over long distances. Edison agreed to work on improving this feature of Bain's machine for the Automatic Telegraph Company (ATC) for $40,000. He improved it to a working speed of 500 words per minute and ran a test between Washington and New York. Hoping to sell their equipment to the Post Office in Britain, ATC sent Edison to England in 1873 to negotiate. A 500-word message was to be sent from Liverpool to London every half-hour for six hours, followed by tests on 2,200 miles (3,540 km) of cable at Greenwich. Only confused results were obtained due to induction in the cable, which lay coiled in a water tank. Edison returned to New York, where he worked on his quadruplex telegraph system, tests of which proved a success between New York and Albany in December 1874. Unfortunately, simultaneous negotiation with Western Union and ATC resulted in a lawsuit.Alexander Graham Bell was granted a patent for a telephone in March 1876 while Edison was still working on the same idea. His improvements allowed the device to operate over a distance of hundreds of miles instead of only a few miles. Tests were carried out over the 106 miles (170 km) between New York and Philadelphia. Edison applied for a patent on the carbon-button transmitter in April 1877, Western Union agreeing to pay him $6,000 a year for the seventeen-year duration of the patent. In these years he was also working on the development of the electric lamp and on a duplicating machine which would make up to 3,000 copies from a stencil. In 1876–7 he moved from Newark to Menlo Park, twenty-four miles (39 km) from New York on the Pennsylvania Railway, near Elizabeth. He had bought a house there around which he built the premises that would become his "inventions factory". It was there that he began the use of his 200- page pocket notebooks, each of which lasted him about two weeks, so prolific were his ideas. When he died he left 3,400 of them filled with notes and sketches.Late in 1877 he applied for a patent for a phonograph which was granted on 19 February 1878, and by the end of the year he had formed a company to manufacture this totally new product. At the time, Edison saw the device primarily as a business aid rather than for entertainment, rather as a dictating machine. In August 1878 he was granted a British patent. In July 1878 he tried to measure the heat from the solar corona at a solar eclipse viewed from Rawlins, Wyoming, but his "tasimeter" was too sensitive.Probably his greatest achievement was "The Subdivision of the Electric Light" or the "glow bulb". He tried many materials for the filament before settling on carbon. He gave a demonstration of electric light by lighting up Menlo Park and inviting the public. Edison was, of course, faced with the problem of inventing and producing all the ancillaries which go to make up the electrical system of generation and distribution-meters, fuses, insulation, switches, cabling—even generators had to be designed and built; everything was new. He started a number of manufacturing companies to produce the various components needed.In 1881 he built the world's largest generator, which weighed 27 tons, to light 1,200 lamps at the Paris Exhibition. It was later moved to England to be used in the world's first central power station with steam engine drive at Holborn Viaduct, London. In September 1882 he started up his Pearl Street Generating Station in New York, which led to a worldwide increase in the application of electric power, particularly for lighting. At the same time as these developments, he built a 1,300yd (1,190m) electric railway at Menlo Park.On 9 August 1884 his wife died of typhoid. Using his telegraphic skills, he proposed to 19-year-old Mina Miller in Morse code while in the company of others on a train. He married her in February 1885 before buying a new house and estate at West Orange, New Jersey, building a new laboratory not far away in the Orange Valley.Edison used direct current which was limited to around 250 volts. Alternating current was largely developed by George Westinghouse and Nicola Tesla, using transformers to step up the current to a higher voltage for long-distance transmission. The use of AC gradually overtook the Edison DC system.In autumn 1888 he patented a form of cinephotography, the kinetoscope, obtaining film-stock from George Eastman. In 1893 he set up the first film studio, which was pivoted so as to catch the sun, with a hinged roof which could be raised. In 1894 kinetoscope parlours with "peep shows" were starting up in cities all over America. Competition came from the Latham Brothers with a screen-projection machine, which Edison answered with his "Vitascope", shown in New York in 1896. This showed pictures with accompanying sound, but there was some difficulty with synchronization. Edison also experimented with captions at this early date.In 1880 he filed a patent for a magnetic ore separator, the first of nearly sixty. He bought up deposits of low-grade iron ore which had been developed in the north of New Jersey. The process was a commercial success until the discovery of iron-rich ore in Minnesota rendered it uneconomic and uncompetitive. In 1898 cement rock was discovered in New Village, west of West Orange. Edison bought the land and started cement manufacture, using kilns twice the normal length and using half as much fuel to heat them as the normal type of kiln. In 1893 he met Henry Ford, who was building his second car, at an Edison convention. This started him on the development of a battery for an electric car on which he made over 9,000 experiments. In 1903 he sold his patent for wireless telegraphy "for a song" to Guglielmo Marconi.In 1910 Edison designed a prefabricated concrete house. In December 1914 fire destroyed three-quarters of the West Orange plant, but it was at once rebuilt, and with the threat of war Edison started to set up his own plants for making all the chemicals that he had previously been buying from Europe, such as carbolic acid, phenol, benzol, aniline dyes, etc. He was appointed President of the Navy Consulting Board, for whom, he said, he made some forty-five inventions, "but they were pigeonholed, every one of them". Thus did Edison find that the Navy did not take kindly to civilian interference.In 1927 he started the Edison Botanic Research Company, founded with similar investment from Ford and Firestone with the object of finding a substitute for overseas-produced rubber. In the first year he tested no fewer than 3,327 possible plants, in the second year, over 1,400, eventually developing a variety of Golden Rod which grew to 14 ft (4.3 m) in height. However, all this effort and money was wasted, due to the discovery of synthetic rubber.In October 1929 he was present at Henry Ford's opening of his Dearborn Museum to celebrate the fiftieth anniversary of the incandescent lamp, including a replica of the Menlo Park laboratory. He was awarded the Congressional Gold Medal and was elected to the American Academy of Sciences. He died in 1931 at his home, Glenmont; throughout the USA, lights were dimmed temporarily on the day of his funeral.[br]Principal Honours and DistinctionsMember of the American Academy of Sciences. Congressional Gold Medal.Further ReadingM.Josephson, 1951, Edison, Eyre \& Spottiswode.R.W.Clark, 1977, Edison, the Man who Made the Future, Macdonald \& Jane.IMcN -

16 Martin, Sir James

SUBJECT AREA: Aerospace[br]b. 1893 Co. Down, Northern Irelandd. 5 January 1981 England[br]Irish military aircraft engineer, inventor of the ejector seat.[br]Martin acquired a general knowledge of engineering as an industrial worker in Belfast. In 1929 he established the Martin Aircraft Company, which was merged five years later with another concern to form the Martin-Baker Aircraft Company at Denham, Buckinghamshire. They became known for designing and constructing efficient, lightweight military aircraft, and Martin supervised personally every aspect of the work of his factory. During the Second World War they developed a number of aircraft weapons, including an explosive device carried on a bomber's wings for cutting the cables of barrage balloons, the flat-feed system for the 20 mm Hispano cannon used on British fighter planes and the twelve-gun pack mounted in the nose of the Havoc night fighter. Martin began devising means of rapid escape from a disabled fighter plane. First came a quick-release canopy for the Spitfire, followed by an improved form sliding on guides set in the fuselage. Then came the Martin-Baker seat, which ejected the pilot from his plane by an explosive charge. Ground tests were made to determine the rates of acceleration that could be tolerated by the pilot, and the first test in the air with a pilot took place in July 1946 at a speed of 320 mph (515 km/h) and an altitude of 8,000 ft (2,400 m). Its first use in a genuine emergency was in May 1949.After the Second World War, the firm specialized in making components, particularly the ejector seat, rather than complete aircraft. The higher speeds and altitudes of supersonic jet aircraft made it necessary to modify the ejector seat: a device to hold the pilot's legs together, to prevent their being broken, was incorporated. In addition, with the Institute of Aviation Medicine, Martin developed a face blind to prevent skin damage at low temperatures. Another modification was to allow the seat to fall freely for the first 10,000 ft (3,000 m) to enable the pilot to reach breathable air more quickly; in October 1959 a successful demonstration took place at 1,250 mph (2,000 km/h) and 40,000 ft (12,000 m) altitude. During the inventor's lifetime, it is estimated that his ejector seat saved the lives of some 4,700 airmen.[br]Principal Honours and DistinctionsKnighted 1965. Barbour Air Safety Award 1958. Cumberbatch Air Safety Trophy 1959. Royal Aero Club Gold Medal 1964.Further ReadingObituary, 1981, The Times.LRD -

17 Murray, Matthew

SUBJECT AREA: Land transport, Mechanical, pneumatic and hydraulic engineering, Railways and locomotives, Steam and internal combustion engines[br]b. 1765 near Newcastle upon Tyne, Englandd. 20 February 1826 Holbeck, Leeds, England[br]English mechanical engineer and steam engine, locomotive and machine-tool pioneer.[br]Matthew Murray was apprenticed at the age of 14 to a blacksmith who probably also did millwrighting work. He then worked as a journeyman mechanic at Stockton-on-Tees, where he had experience with machinery for a flax mill at Darlington. Trade in the Stockton area became slack in 1788 and Murray sought work in Leeds, where he was employed by John Marshall, who owned a flax mill at Adel, located about 5 miles (8 km) from Leeds. He soon became Marshall's chief mechanic, and when in 1790 a new mill was built in the Holbeck district of Leeds by Marshall and his partner Benyon, Murray was responsible for the installation of the machinery. At about this time he took out two patents relating to improvements in textile machinery.In 1795 he left Marshall's employment and, in partnership with David Wood (1761– 1820), established a general engineering and millwrighting business at Mill Green, Holbeck. In the following year the firm moved to a larger site at Water Lane, Holbeck, and additional capital was provided by two new partners, James Fenton (1754–1834) and William Lister (1796–1811). Lister was a sleeping partner and the firm was known as Fenton, Murray \& Wood and was organized so that Fenton kept the accounts, Wood was the administrator and took charge of the workshops, while Murray provided the technical expertise. The factory was extended in 1802 by the construction of a fitting shop of circular form, after which the establishment became known as the "Round Foundry".In addition to textile machinery, the firm soon began the manufacture of machine tools and steam-engines. In this field it became a serious rival to Boulton \& Watt, who privately acknowledged Murray's superior craftsmanship, particularly in foundry work, and resorted to some industrial espionage to discover details of his techniques. Murray obtained patents for improvements in steam engines in 1799, 1801 and 1802. These included automatic regulation of draught, a mechanical stoker and his short-D slide valve. The patent of 1801 was successfully opposed by Boulton \& Watt. An important contribution of Murray to the development of the steam engine was the use of a bedplate so that the engine became a compact, self-contained unit instead of separate components built into an en-gine-house.Murray was one of the first, if not the very first, to build machine tools for sale. However, this was not the case with the planing machine, which he is said to have invented to produce flat surfaces for his slide valves. Rather than being patented, this machine was kept secret, although it was apparently in use before 1814.In 1812 Murray was engaged by John Blenkinsop (1783–1831) to build locomotives for his rack railway from Middleton Colliery to Leeds (about 3 1/2 miles or 5.6 km). Murray was responsible for their design and they were fitted with two double-acting cylinders and cranks at right angles, an important step in the development of the steam locomotive. About six of these locomotives were built for the Middleton and other colliery railways and some were in use for over twenty years. Murray also supplied engines for many early steamboats. In addition, he built some hydraulic machinery and in 1814 patented a hydraulic press for baling cloth.Murray's son-in-law, Richard Jackson, later became a partner in the firm, which was then styled Fenton, Murray \& Jackson. The firm went out of business in 1843.[br]Principal Honours and DistinctionsSociety of Arts Gold Medal 1809 (for machine for hackling flax).Further ReadingL.T.C.Rolt, 1962, Great Engineers, London (contains a good short biography).E.Kilburn Scott (ed.), 1928, Matthew Murray, Pioneer Engineer, Leeds (a collection of essays and source material).C.F.Dendy Marshall, 1953, A History of Railway Locomotives Down to the End of theYear 1831, London.L.T.C.Rolt, 1965, Tools for the Job, London; repub. 1986 (provides information on Murray's machine-tool work).Some of Murray's correspondence with Simon Goodrich of the Admiralty has been published in Transactions of the Newcomen Society 3 (1922–3); 6(1925–6); 18(1937– 8); and 32 (1959–60).RTS -

18 навесной замок

навесной замок

-Параллельные тексты EN-RU

...be provided with a means permitting it to be locked in the OFF (isolated) position (for example by padlocks).

[IEC 60204-1-2006]... иметь средства для запирания в положении ОТКЛЮЧЕНО (отделено), например, с помощью навесных замков.

[Перевод Интент]

Источник: insight-security.com

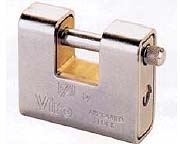

In simple terms, a padlock has three major components; the Body, the Shackle and the Locking Mechanism, …it may also incorporate features such as a weatherproof casing, anti drill or anti cropping protection, etc.

Discus style padlocks - have no angular corners, so are often used with cycle security chains and cables, as well as being a popular choice for securing doors on sheds and beach huts, etc. When used as a door lock, they will typically be used in conjunction with the special shrouded discus hasp and staple set, which offers extra protection to the padlock shackle.

Shutter Locks / Anvil Locks - are typically used to secure the external (or internal) security roller shutters fitted to shop fronts. They are also popular for use with parking posts, motorcycle security chains, etc.

Conventional Style padlocks have a wide range of applications from low security applications like locking your toolbox, to high security uses such as securing factory gates or protecting motorcycles. They are typically available as; Open, Close, or Semi Enclosed Shackle types

Shackleless type padlock (shown with special hasp)Shackleless Padlocks - this is a bit of a misnomer as the padlock does of course have a shackle, it’s just that it’s on the underside of the lock body and therefore unseen. This type of padlock can be round (like the one pictured) or rectangular, but typically, they are designed to be used with a special matching security hasp. Because of their design, these units are difficult to attack and over recent years, as well as being used on warehouse doors, etc, they have also become very popular for use on vans and other vehicles where they are used to secure opening double doors.

A "Close Shackle" padlock is one with built in shoulders, which are designed to minimise the amount of the shackle exposed, to a saw or bolt cropper attack. This type of padlock will normally have a higher security rating than an equivalent unit with a semi enclosed or open shackle, however subject to size and clearances, may not be practical for instance, to use where you need to secure 2 chain links together or require a padlock for use with a shrouded hasp, etc. To make them easier to use, many Close Shackle padlocks feature "removable shackles" which are fully released from the body of the padlock when it's unlocked.

An "Open Shackle" padlock will typically be easier to use where the shackle needs to pass through 2 chain-links (i.e, a chain securing two opening gates together), etc. As more of the shackle is exposed however, this makes it potentially easier to attack with a saw or bolt croppers.

A "Semi Enclosed Shackle" padlock is something of a compromise, but will often offer more flexibility in use than a Close Shackle padlock and improved security over an Open Shackle model.

Тематики

EN

Русско-английский словарь нормативно-технической терминологии > навесной замок

См. также в других словарях:

components factory — /kəm pəυnənts ˌfækt(ə)ri/ noun a factory which makes parts which are used in other factories to make finished products … Marketing dictionary in english

Factory Five Racing — Infobox Company company name = Factory Five Racing, Inc. company company type = Privately Owned company slogan = The World s Number One Selling Replicars foundation = 1995 location = flagicon|USA Wareham, Massachusetts, USA key people = Mark… … Wikipedia

Factory farming — A commercial chicken house raising broiler pullets for meat … Wikipedia

factory system — ▪ industry system of manufacturing that began in the 18th century and is based on the concentration of industry into specialized and often large establishments. The system arose in the course of the Industrial Revolution. The factory… … Universalium

Software factory — In software engineering and enterprise software architecture, a software factory is an organizational structure that specializes in producing computer software applications or software components according to specific, externally defined end user … Wikipedia

FŁT-Kraśnik SA - rolling bearings factory — A Joint Stock Company, which belongs to the Treasury, with its premises located in Kraśnik, 50 km south west of Lublin, near the eastern border of EU (European Union). The main products of the FŁT Kraśnik are bearings and their components… … Wikipedia

Microsoft Data Access Components — MDAC redirects here. For other uses, see MDAC (disambiguation). MDAC (Microsoft Data Access Components) Microsoft Corporation s MDAC provides a uniform framework for accessing a variety of data sources on their Windows platform. Developer(s)… … Wikipedia

Chiaphua Components Group — Chiahpua Components Group 捷和电机集团 Type Private owned company 私营企业 Industry Manufacturing 制造业 Founded 1987 Headquarters Hong Kong 香港 Area served Worldwide 世界 Key people … Wikipedia

Malyshev Factory — Malyshev Plant Type state owned company Industry arms industry, machine building Founded 1895 … Wikipedia

Al-Shifa pharmaceutical factory — The Al Shifa (Arabic for healing ) pharmaceutical factory in Khartoum North, Sudan was constructed between 1992 and 1996 with components imported from the United States, Sweden, Italy, Switzerland, Germany, India, and Thailand. The industrial… … Wikipedia

Royal Aircraft Factory F.E.2 — F.E.2b F.E.2b with V type undercarriage Role Fighter/Reconnaissance … Wikipedia